Letters From The Science Team

June 21st, 2023

Dosing Explained – Percent, PPM, Dilution Ratios

Background

When adding any chemical to a hydroponic system, it is critical to understand the dosing rate, dosing schedule, and acceptable applied concentration in solution. A proper understanding of these concepts is necessary to effectively control pathogens through chemical means and avoid chemically induced phytotoxicity.

Dosing: Percent, PPM, Dilution Ratios

When growers add a chemical to their hydroponic system, they are typically adding a concentrated form of the chemical, referred to as a chemical stock solution. These concentrated stock solutions are added to systems using dilution ratios to achieve desirable active ingredient concentration within the system.

Acceptable chemical concentrations and phytotoxic thresholds are unique to each chemical, use case, and plant species being treated. Once the appropriate dosing concentration and dosing schedule has been determined, horticulturalists must calculate how much chemical stock solution should be used to achieving the desired final concentration.

To determine the starting concentration of any commercial chemical stock solution, check the Safety Data Sheet (SDS). All commercially available chemical products are required to list the active ingredient concentrations in an SDS. Typically, active ingredients are listed by percent weight - that is, the percent weight of the active ingredient relative to the total weight of the solution. Active ingredient concentrations can vary widely between similar products with the same active ingredients. For example, commercially available forms of hydrogen peroxide (H2O2) can be purchased in stock solution concentrations between 3% and 35%.

Labels attached to most commercially available chemical cleaning agents provide recommended dilution ratios for specific applications. While these dilution ratios serve as important references, it is important the final concentration of active ingredient in solution achieved by following the dilution ratios is also well understood. Traditionally, one would use the formula C1V1=C2V2 to calculate volumes and concentrations, but there is also a simple method to use.

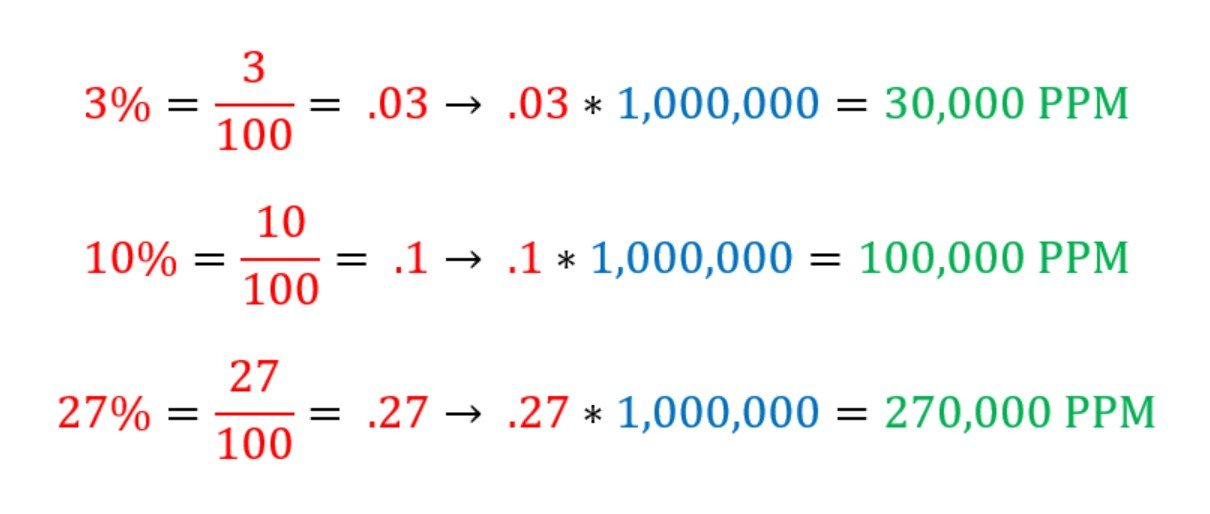

The concentration of any chemical in a solution is best described by determining the number of “parts per million” (PPM) of that chemical in the solution. The PPM of any ingredient in solution can be calculated from the percent weight. The PPM of active ingredient in a 3% stock solution can be calculated by finding 3% of 1,000,000. Following this logic, a 3%, 27%, and 35% stock solution will have equivalent PPM values of 30,000, 270,000, and 350,000 respectively.

Converting Percent Weight To PPM

Alternatively, percent weight can be converted to PPM by multiplying the raw percent weight value by 10,000.

Converting Percent Weight to PPM (Shortcut)

The same basic arithmetic can be used to determine the final concentration of active ingredient in solution following any dilution ratio. For example, adding 27% hydrogen peroxide solution at a dilution ratio of 1:2000 will result in a 135 PPM of hydrogen peroxide in the final solution.

Converting 27% to PPM

Applying 270,000 PPM Stock Solution at 1 to 2,000 Rate

Using these tools, horticulturalists can also calculate their own dilution ratios to achieve a desired concentration of active ingredient in solution using any concentration of stock solution.

In our next letter, we will cover a summary of Aeroponic cleaning topics.

Questions?

Letters From The Science Team

November 30th, 2022

H2O2 Explained

Background

Disinfecting fertigation water prior to and during use is critical for minimizing potential transmissions of pathogens. As a strong oxidizer, H2O2 can be applied to prevent the growth of plant pathogens within fertigation water. While H2O2 can be used to treat established pathogens, it is most effective when used as a preventative treatment.

Dosing: Acceptable Applied Concentrations & Avoiding Phytotoxicity

When applying any chemical for pathogen control in soilless hydroponic systems, understanding the acceptable applied concentrations for the concerned plants is critical for avoiding adverse effect on plant growth, or phytotoxicity. The acceptable applied concentration, (and concentration threshold) for phytotoxicity is dependent on the plant species and method of application.

Commercially available forms of H2O2 are sold in a variety of different concentrations. Typically, hydrogen peroxide is available for purchase in concentrations of 3%, 26%, and 35%. All commercial chemical products are required to list the concentration of their active ingredients on their product Safety Data Sheet (SDS), which can usually be found online.

In most cases, an acceptable H2O2 concentration in solution for different applications can be extrapolated from product-specific dilution ratios. Typical concentrations of H2O2 in solution for different applications can range between 25-150 PPM depending on exposure time, the concentration of organic matter in solution, plant species, and plant age. In appropriate contexts, higher concentrations can be advisable, but doing so can risk phytotoxicity.

H2O2 Chemistry and Horticultural Utility

When added to water, hydrogen peroxide reacts to form H2O and a wide variety of free radicals and other reactive species capable of reacting with and decomposing organic material, including pathogens. Regardless of the intermediate reaction steps, the final by-products of H2O2 are oxygen and water.

Due to its highly reactive nature and lack of harmful disinfection by-products, H2O2 is considered especially helpful for cleaning hydroponic and aeroponic fertigation systems. The reactive molecules generated during H2O2 decomposition react with organic matter present in water systems, reducing stability of cell membranes, cellular proteins, and in some cases DNA. This reaction

is non-selective, meaning H2O2 will oxidize all components of the fertigation water as well as tissues from any crops being irrigated – it is due to this that H2O2 dosing concentrations should reflect crop-specific phytotoxic thresholds.

H2O2 Decomposition

The rate of applied H2O2 decomposition in hydroponic systems depends on the concentration of exposed organic matter, the presence or absence of chemical stabilizers, and the applied concentration. When introduced to water, H2O2 breaks down rapidly. In many cases, commercial “activators” are added to stabilize the original solution and to increase the efficacy of the product. When added to active soilless hydroponic systems at concentrations below 100 PPM, the concentration of hydrogen peroxide typically decomposes rapidly within a few hours, with little or no traceable amount present in solution after 24-48 hours.

H2O2 and ORP

The oxidizing potential of H2O2 is greater than that of hypochlorous acid and chlorine dioxide. Despite being a powerful oxidizer, ORP is not a practical method for monitoring the antimicrobial potential of water treated with hydrogen peroxide. The relationship between the applied concentration of H2O2 and ORP is non-linear at the typically applied concentrations used for disinfecting water. As such, the antimicrobial potential of water should be extrapolated by monitoring active concentration of H2O2 in solution using test strips or other

Questions?

Letters From The Science Team

December 7th, 2022

HOCl (Hypochlorous Acid) Introduced

Background

Disinfecting fertigation water prior to and during use is critical for minimizing pathogen establishment and transmission. Chlorine has been used to disinfect water for over one hundred years. While water chlorination can take many forms, a selective few are appropriate for hydroponic applications. Hypochlorous acid is one form of chlorine that is highly effective at disinfecting and maintaining water cleanliness in hydroponic systems. Despite its general utility, the instability of hypochlorous acid in solution and the creation of disinfection by-products can cause issues if not properly addressed.

Free Chlorine - Chemical forms of Chlorine in Solution

Free chlorine refers to the chlorine in solution that has yet to bind to microbes or chemicals. These molecules are “free” to react with contaminants that may exist or be introduced. One of three free chlorine molecules can be generated when chlorine containing compounds are added to water. The relative extent to which each form is produced is dictated by the pH of the solution. Below a pH of 4, chlorine gas is formed (Cl2). Between a pH of 5 and 7, hypochlorous acid (HOCl) is the dominant form of free chlorine generated in solution. Above a pH value of 8, hypochlorite ions (OCl-) are generated predominantly. Of these free chlorine species, hypochlorous acid is most favorable for use as a cleaning and disinfecting agent in hydroponic systems.

Utility of Hypochlorous Acid

Hypochlorous acid is an effective disinfecting agent that is safe for human contact. In fact, human white blood cells produce hypochlorous acid to fight infections. Hypochlorous acid’s strong oxidizing potential, combined with its neutral charge, grant it exceptional bactericidal, fungicidal, and viricidal properties.

When added to a hydroponic system, the free hypochlorous acid in solution reacts rapidly with the fertigation water creating combined chlorines or chloramines - “spent” free chlorine that has that has bound itself to a contaminant or ammonium containing compounds.

Bleach vs. Hypochlorous Acid

The chlorine containing compound used to generate free chlorine in bleach is sodium hypochlorite (NaOCl). To reduce decomposition, bleach solutions are typically buffered with the strong base sodium hydroxide (NaOH). As a result, the pH of most bleach solutions is between 11-13. At this pH range, the dominant free chlorine species found in bleach are hypochlorite ions. Because most pathogenic bacterial, fungal, and viral cell walls are also negatively charged, hypochlorite ions are magnetically repelled from them. For this reason, hypochlorous acid is a much more effective disinfectant than bleach.

Sourcing Hypochlorous Acid

Commercially available forms of hypochlorous acid for use in hydroponic systems are sold in a variety of concentrations, most of which can be found on the products Safety Data Sheet (SDS). Typically, hypochlorous acid sold for use in hydroponic systems are sold in either .028%, .04%, .05%, or .15% concentrations.

Generating Hypochlorous acid

Hypochlorous acid can also be generated for use on site using different methods. The most common is generation by electrolysis using a commercially available electrolyzed water generator. The titanium electrolysis cell within the higher quality electrolyzed water generators can produce 1 liter of .02% hypochlorous acid at solution within 16 minutes using only tap water, vinegar (to maintain pH between 5 and 7), and table salt. Higher concentrations can be generated by running the electrolysis cells for additional time.

In our next letter we will take a deeper look at storing and dosing Hypochlorous acid.

Questions?

Letters From The Science Team

December 15th, 2022

Hypochlorous Acid Decomposition In Storage

All free chlorine species, including hypochlorous acid, are unstable and will decompose overtime. Purchased Hypochlorous acid solutions typically have a 90 day shelf life after opening, whereas hypochlorous acid generated on site can decompose within 24-48 hours.

Dosing Hypochlorous Acid

At low concentrations in solution (.3-.8 PPM), hypochlorous acid works effectively as a mineral descaler and irrigation line cleaner. At higher concentrations in solution (.8-2.5 PPM), hypochlorous acid can also work as an effective oxidative cleaning agent with minimal risk of phytotoxicity. Unlike other hydroponic chemical oxidizers, the recommended hypochlorous acid application rates provided by manufacturers will not often be sufficient for the treatment or prevention of pathogens, as the recommendations typically reflect the products application as a descaling product, rather than an oxidizer cleaning agent.

Because hypochlorous acid reacts rapidly with organic matter and ammonium containing fertilizers, dosing hypochlorous acid for disinfection purposes can be tricky. In practice, dosing hypochlorous acid incorrectly, even at high concentrations, can result in rapid decomposition of the free chlorine, resulting in little or no change in pathogen presence. The rate of applied hypochlorous acid decomposition in hydroponic systems depends on the concentration of exposed organic matter, the presence of ammonium containing fertilizers, and the applied concentration of hypochlorous acid.

In our testing, the most effective way to utilize hypochlorous acid as an oxidative preventative cleaning agent is to apply the hypochlorous acid immediately following a flush at a high concentration (.8-2.5 PPM) to a small volume of pH corrected reservoir

water that is circulated throughout the system for at least one hour before adding additional water and nutrients. By doing so, the free hypochlorous acid in solution is effectively “spent” sanitizing any latent pathogens in the root zone and piping systems, not the ammonium containing elements in the fertilizer or the organic matter in the nutrient solution pre-flush. Ideally, the reservoir and root zone area are also hand cleaned before the hypochlorous application to further reduce the organic matter the hypochlorous acid will meet, allowing more effective and thorough disinfection. A more aggressive range of 2.5 – 5 PPM free hypochlorous acid can be used to help control established pathogens, however it should be noted that sustained hypochlorous acid concentrations above 2.5 PPM can cause phytotoxicity.

Hypochlorous Acid and ORP

A measurable change in ORP following an application of hypochlorous acid is typically observed; however, in our testing, the relationship between the applied concentration of hypochlorous acid and the change in ORP did not correlate well at levels below 15 PPM. Therefore, the disinfection potential of water treated with hypochlorous acid should not be extrapolated by monitoring the ORP. Instead, the disinfection potential of the water should be extrapolated by monitoring the active concentration of free chlorine in solution by using free chlorine test strips or other colorimetric methods. Despite ORP not being a practical method for informing dosing decisions at the typically applied concentrations used for disinfecting water in hydroponic systems, it can still be utilized as a secondary reference point when developing dosing regimens using hypochlorous acid products over long periods of time.